AR Maintenance Solution NxtMove

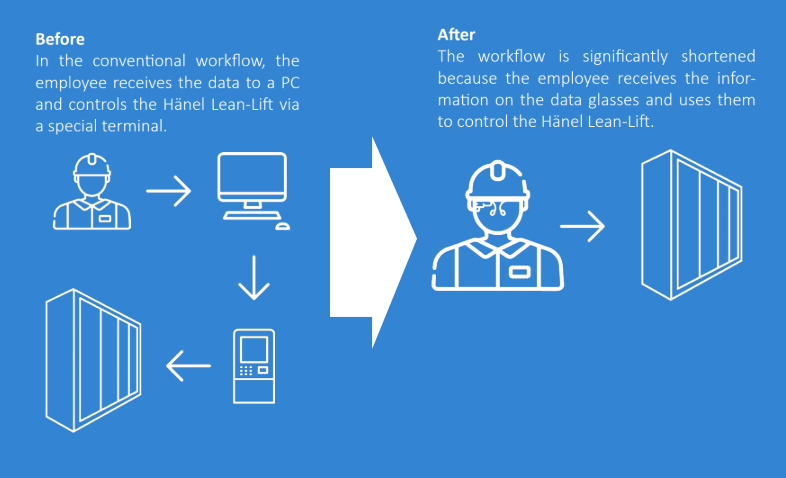

In intralogistics, ever larger quantities of goods are handled today. To ensure optimum use of the available storage space, many companies use Hänel Lean-Lifts with variable stowage heights as high-bay warehouses. However, the processes for storage and order picking are complicated and require intensive instruction in the operation of the Hänel Lean-Lift. To request articles, article number and/or article description must be entered via a PC or an operating terminal. Previously, the pick lists from the Warehouse Management System were printed on paper and then processed manually by the employee. This process offers extensive error potential due to media breaks and additionally requires increased control effort.

Source : NxtBase

Solution and benefits

Their solution :

The warehouse worker receives a selection of the articles available on the respective Hänel Lean-Lift or a list to be processed directly on his data glasses. He can request and remove the desired articles by voice command. The number of remaining articles in the respective storage box is also checked. In this way, for example, a permanent inventory is also possible.

Your benefits

Voice control significantly shortens access times to the articles in the Hänel Lean-Lift. The employee can request the next article as soon as he has finished removing the previous one. The ergonomics of the workstation is significantly improved, as the employee does not have to work in between the operator terminal and make complicated entries there. The entire process is faster, paperless and thus increases the productivity of the employee.

source : Nxtbase